Sustainability

-

Materials.

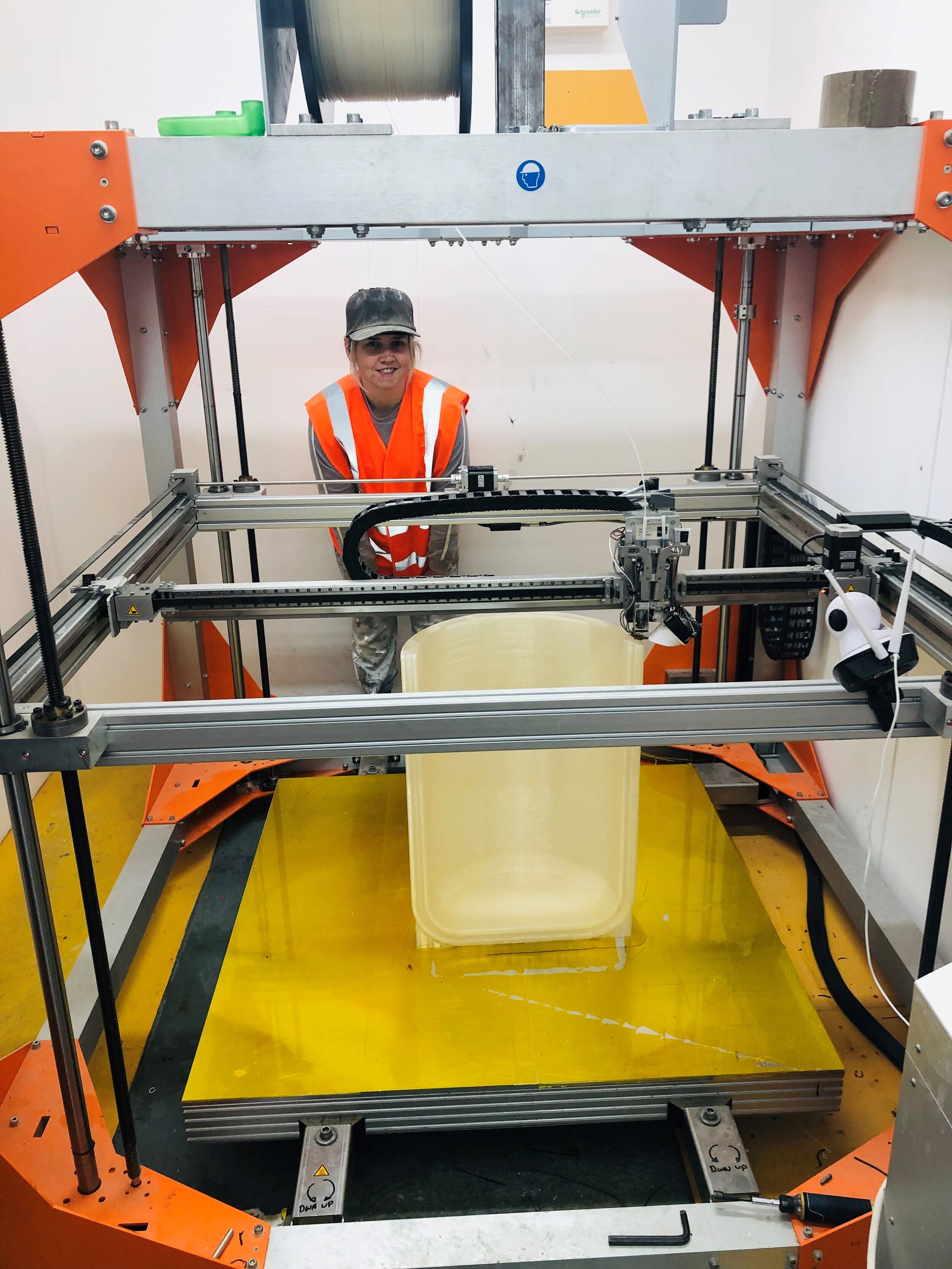

GPM is continually looking for ways to introduce more eco-friendly materials into our manufacturing process. The majority of models we produce today are 3D-printed, and for these projects, we use polylactide (PLA) filament. Considered a 'ecoplastic', PLA is processed from plant starch and other renewable raw materials. PLA is also a thermoplastic and can be melted and reshaped for reuse.

-

Waste Reduction.

All our engineers reuse materials wherever suitable and are committed to our waste-less vision. GPM has dedicated storage points on-site for cut-offs that hold the potential for reuse in future projects. We also recycle as much supplier packaging as possible: wood, cardboard and paper products.

-

Technology.

Technology plays a vital role in achieving our sustainability and waste reduction goals. Our CNC machining/laser-cutting software has a ‘nesting’ function, which calculates the most material-efficient way to cut parts out of sheet material for waste reduction. Our 3D-printing software automatically calculates material-conserving internal structures, hollowing out interior spaces in models where possible. 3D printing utilises additive manufacturing technology, using only the amount of material required to make the part.